Brief Basics: LINE Scan output stages operate on the same basic principle whether

the active device used is a valve, transistor or thyristor. As a

starting point, let's remind ourselves of this principle, which was

first developed by Blumlein in 1932. The idea in its simplest form is

shown in Fig. 1. The scan coils, together with a parallel tuning

capacitor, are connected in series with a switch across the h.t. supply.

When the switch is closed - (a) - current flows through the coils,

building up linearly as required to deflect the beam from the centre to

the right-hand side of the screen. At this point the switch is opened.

The coils and the capacitor then form a resonant circuit. The magnetic

fields generated around the coils during the preceeding forward scan as

current flowed through them when the switch was closed now collapse,

charging the capacitor - (b). As a result of the resonant action the

capacitor next discharges, driving current through the coils in the

opposite direction - (c). Once more magnetic fields are generated around

the coils. This resonant action lasts for one half -cycle of

oscillation, during which the beam is rapidly deflected from the right-

hand side to the centre and then to the left-hand side of the screen.

The flyback is thus complete. If the switch is now closed again further

oscillation is prevented and, as the magnetic fields around the coils

collapse, a decaying current flows through them in the direction shown

at (d). This decaying current flow deflects the beam from the left-hand

side of the screen back towards the centre: the period during which this

occurs is often referred to as the energy recovery part of the scanning

cycle. When the current has decayed to zero we are back at the

situation shown at (a): the current through the coils reverses, driving

the beam to the right-hand side of the screen. This is a very efficient

System, since most of the energy drawn from the supply is subsequently

returned to it. There is negligible resistance in the circuit, so there

is very little power loss.

Brief Basics: LINE Scan output stages operate on the same basic principle whether

the active device used is a valve, transistor or thyristor. As a

starting point, let's remind ourselves of this principle, which was

first developed by Blumlein in 1932. The idea in its simplest form is

shown in Fig. 1. The scan coils, together with a parallel tuning

capacitor, are connected in series with a switch across the h.t. supply.

When the switch is closed - (a) - current flows through the coils,

building up linearly as required to deflect the beam from the centre to

the right-hand side of the screen. At this point the switch is opened.

The coils and the capacitor then form a resonant circuit. The magnetic

fields generated around the coils during the preceeding forward scan as

current flowed through them when the switch was closed now collapse,

charging the capacitor - (b). As a result of the resonant action the

capacitor next discharges, driving current through the coils in the

opposite direction - (c). Once more magnetic fields are generated around

the coils. This resonant action lasts for one half -cycle of

oscillation, during which the beam is rapidly deflected from the right-

hand side to the centre and then to the left-hand side of the screen.

The flyback is thus complete. If the switch is now closed again further

oscillation is prevented and, as the magnetic fields around the coils

collapse, a decaying current flows through them in the direction shown

at (d). This decaying current flow deflects the beam from the left-hand

side of the screen back towards the centre: the period during which this

occurs is often referred to as the energy recovery part of the scanning

cycle. When the current has decayed to zero we are back at the

situation shown at (a): the current through the coils reverses, driving

the beam to the right-hand side of the screen. This is a very efficient

System, since most of the energy drawn from the supply is subsequently

returned to it. There is negligible resistance in the circuit, so there

is very little power loss. ok

at the power supply requirements can be simplified (a line output

transistor must be operated in conjunction with a stabilised power

supply: this is not necessary in the thyristor circuit since regulation

can be built in). In the nature of things however there must be

disadvantages as well - and there are! First, a thyristor will not act

as a bidirectional switch.

ok

at the power supply requirements can be simplified (a line output

transistor must be operated in conjunction with a stabilised power

supply: this is not necessary in the thyristor circuit since regulation

can be built in). In the nature of things however there must be

disadvantages as well - and there are! First, a thyristor will not act

as a bidirectional switch.  A

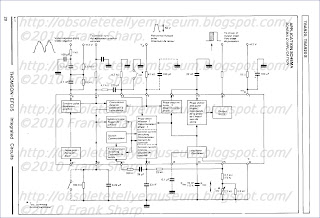

more practical arrangement is shown in Fig. 4. A secondary winding L3

is added to Ll to provide the trigger pulse for TH2: L4, C4 and R I

provide the pulse shaping required. The tuning capacitor Ct is

rearranged as a T network: this is done to reduce the voltage across the

individual capacitors and enable smaller values to be used, all in the

interests of economy. And finally a transformer is coupled to the

circuit by C5 to make use of the flyback pulse for e.h.t. generation and

to provide other supplies. In many recent chassis THUD 1 and TH2/D2 are

encapsu- lated together, in pairs. In practical circuits L1 and L2

generally consist of a single transformer - often a transductor is used,

for convenience rather than for the transductor characteristics. This

makes practical circuits look at first glance rather different to the

basic form shown in Figs. 3 and 4. A further winding is often added to

the transformer to provide a supply for other parts of the receiver,

making the circuit look even more confusing. In addition e.h.t.

regulation, pincushion distortion correction and beam limiting circuitry

is required, and protection circuits may be incorporated.

A

more practical arrangement is shown in Fig. 4. A secondary winding L3

is added to Ll to provide the trigger pulse for TH2: L4, C4 and R I

provide the pulse shaping required. The tuning capacitor Ct is

rearranged as a T network: this is done to reduce the voltage across the

individual capacitors and enable smaller values to be used, all in the

interests of economy. And finally a transformer is coupled to the

circuit by C5 to make use of the flyback pulse for e.h.t. generation and

to provide other supplies. In many recent chassis THUD 1 and TH2/D2 are

encapsu- lated together, in pairs. In practical circuits L1 and L2

generally consist of a single transformer - often a transductor is used,

for convenience rather than for the transductor characteristics. This

makes practical circuits look at first glance rather different to the

basic form shown in Figs. 3 and 4. A further winding is often added to

the transformer to provide a supply for other parts of the receiver,

making the circuit look even more confusing. In addition e.h.t.

regulation, pincushion distortion correction and beam limiting circuitry

is required, and protection circuits may be incorporated. transformer's primary winding. By feeding a field frequency waveform to

the control winding on this transductor the line scanning is modulated

at field frequency. There is a simple but effective safety circuit in

this Grundig line output stage. If the voltage at tag c on the line

output transformer rises above 68V zener diode Di514 conducts,

triggering thyristor Ty511 into conduction with the result that the

cut-out operates. C517 is returned to chassis via a damped coil (L517)

so that the voltage transient when the efficiency diode cuts off is

attenuated. Likewise L512/C512/R512 are added to suppress the voltage

transient when the flyback thyristor Ty511 cuts off. The balancing coil

L516 is included to remove unwanted voltage spikes produced by the

thyristors.

transformer's primary winding. By feeding a field frequency waveform to

the control winding on this transductor the line scanning is modulated

at field frequency. There is a simple but effective safety circuit in

this Grundig line output stage. If the voltage at tag c on the line

output transformer rises above 68V zener diode Di514 conducts,

triggering thyristor Ty511 into conduction with the result that the

cut-out operates. C517 is returned to chassis via a damped coil (L517)

so that the voltage transient when the efficiency diode cuts off is

attenuated. Likewise L512/C512/R512 are added to suppress the voltage

transient when the flyback thyristor Ty511 cuts off. The balancing coil

L516 is included to remove unwanted voltage spikes produced by the

thyristors.  LARGELY

due to advances in colour c.r.t. scan coil design, the thyristor line

output stage has become obsolete laready in the 1981's.

LARGELY

due to advances in colour c.r.t. scan coil design, the thyristor line

output stage has become obsolete laready in the 1981's. s type used polyester capacitors, and it's no surprise that they were

inclined to give up. When replacing the tuning capacitors in a

thyristor line output stage it's essential to use polypropylene types -a

good range of axial components with values ranging from 0.001µF to

047µF is available from RS Components, enabling even non-standard values

to be made up from an appropriate combination. Using polypropylene

capacitors in place of polyester ones will not only ensure capacitor

reliability but will also lower the stress on other components by

reducing the circuit losses (and hence power consumption).

s type used polyester capacitors, and it's no surprise that they were

inclined to give up. When replacing the tuning capacitors in a

thyristor line output stage it's essential to use polypropylene types -a

good range of axial components with values ranging from 0.001µF to

047µF is available from RS Components, enabling even non-standard values

to be made up from an appropriate combination. Using polypropylene

capacitors in place of polyester ones will not only ensure capacitor

reliability but will also lower the stress on other components by

reducing the circuit losses (and hence power consumption). e

right of the tuning capacitance acts in exactly the same manner as a

transis- tor line output stage, with the scan thyristor Th2 replacing

the transistor. The thyristor is switched on about half way through the

forward scan, the efficiency diode D2 provid- ing the initial part of

the line scan (left-hand side of the screen). The scan coils and line

output transformer (used to generate the e.h.t. plus various other

supply lines and pulse waveforms as required) are a.c. coupled, via the

scan -correction capacitor C5 and C6 respectively. The problem with a

thyristor is that it can be turned on at its gate but not off. To switch

a thyristor off, the current flowing through it must be reduced below a

value known as the hold -on current. This is the main function of the

components on the left-hand side - the line generator, the flyback

thyristor with its parallel diode and the commutat- ing coil. During the

forward scan, the tuning capacitors are charged from the h.t. line via

the input and commutat- ing coils. The line generator produces a pulse

to trigger the flyback thyristor Th1- this occurs just before the actual

flyback. When Thl1 switches on, the junction of the input coil and the

commutating coil is momentarily con- nected to chassis. The tuning

capacitance and the com- mutating coil then resonate, producing a pulse

which draws current via the scan thyristor. Since this current flow is

in the opposite direction to the scan current flow, the two cancel and

the current flowing via the scan thyris- tor falls below the hold -on

current. Th2 is thus switched off, and the scan coils resonate with the

tuning capaci- tance to provide the flyback action. So much for the

basic action. A secondary winding coupled to the input coil produces a

pulse to switch the scan thyristor on, in conjunction with the

shaping/delay network Ll, C4, R1. The tuning capacitors are usually

arranged in the T formation shown to reduce the values required and the

voltages developed across them. In practical circuits the input

and commutating coils are usually combined in a single unit which for

obvious reasons is generally known as the combi coil. The main point not

so far mentioned is stabilisation. There are two approaches to this. In

earlier circuits a transductor was included in parallel with the

e

right of the tuning capacitance acts in exactly the same manner as a

transis- tor line output stage, with the scan thyristor Th2 replacing

the transistor. The thyristor is switched on about half way through the

forward scan, the efficiency diode D2 provid- ing the initial part of

the line scan (left-hand side of the screen). The scan coils and line

output transformer (used to generate the e.h.t. plus various other

supply lines and pulse waveforms as required) are a.c. coupled, via the

scan -correction capacitor C5 and C6 respectively. The problem with a

thyristor is that it can be turned on at its gate but not off. To switch

a thyristor off, the current flowing through it must be reduced below a

value known as the hold -on current. This is the main function of the

components on the left-hand side - the line generator, the flyback

thyristor with its parallel diode and the commutat- ing coil. During the

forward scan, the tuning capacitors are charged from the h.t. line via

the input and commutat- ing coils. The line generator produces a pulse

to trigger the flyback thyristor Th1- this occurs just before the actual

flyback. When Thl1 switches on, the junction of the input coil and the

commutating coil is momentarily con- nected to chassis. The tuning

capacitance and the com- mutating coil then resonate, producing a pulse

which draws current via the scan thyristor. Since this current flow is

in the opposite direction to the scan current flow, the two cancel and

the current flowing via the scan thyris- tor falls below the hold -on

current. Th2 is thus switched off, and the scan coils resonate with the

tuning capaci- tance to provide the flyback action. So much for the

basic action. A secondary winding coupled to the input coil produces a

pulse to switch the scan thyristor on, in conjunction with the

shaping/delay network Ll, C4, R1. The tuning capacitors are usually

arranged in the T formation shown to reduce the values required and the

voltages developed across them. In practical circuits the input

and commutating coils are usually combined in a single unit which for

obvious reasons is generally known as the combi coil. The main point not

so far mentioned is stabilisation. There are two approaches to this. In

earlier circuits a transductor was included in parallel with the  input

coil to vary the impe- dance in series with the tuning capacitance.

This was driven by a transistor which was in turn controlled by feedback

from the line output transformer. A more efficient technique is used in

later circuits, with a current dumping thyristor in series with the

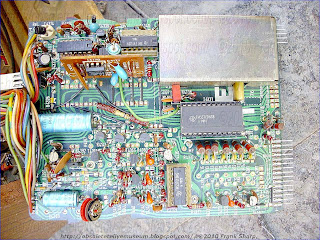

input coil. Practical Circuit As a typical example of the earlier type

of circuit, Fig. 2 shows the thyristor line output stage used in the

Grundig 5010/5011/6010/6011 series. Td1 is the regulating transductor

which is driven by Tr506. Ty511 is the flyback thyristor (commutating

thyristor might be a better name), Ty518 the scan thyristor, Di518 the

efficiency diode and C516/7/8 the tuning capacitance. The scan coils are

cou- pled via C537, while C532 provides coupling between the primary

winding of the line output transformer and chas- sis. A transductor

(Td2) is used for EW raster correction. The combi coil also feeds 1.t.

rectifiers from its secondary windings.

input

coil to vary the impe- dance in series with the tuning capacitance.

This was driven by a transistor which was in turn controlled by feedback

from the line output transformer. A more efficient technique is used in

later circuits, with a current dumping thyristor in series with the

input coil. Practical Circuit As a typical example of the earlier type

of circuit, Fig. 2 shows the thyristor line output stage used in the

Grundig 5010/5011/6010/6011 series. Td1 is the regulating transductor

which is driven by Tr506. Ty511 is the flyback thyristor (commutating

thyristor might be a better name), Ty518 the scan thyristor, Di518 the

efficiency diode and C516/7/8 the tuning capacitance. The scan coils are

cou- pled via C537, while C532 provides coupling between the primary

winding of the line output transformer and chas- sis. A transductor

(Td2) is used for EW raster correction. The combi coil also feeds 1.t.

rectifiers from its secondary windings.  Component Problems: The only problem with this type of circuit is the large amount of energy that shuttles back and forth at line frequency.

This places a heavy stress on certain components. Circuit losses

produce quite high temperatures, which are concentrated at certain

points, in particular the combi coil. This leads to deterioration of the

soldered joints around the coil, a common cause of failure. This can

have a cumulative effect, a high -resistance joint increasing the local

heating until the joint becomes well and truly dry -a classic symptom

with some Grundig sets. The wound components themselves can be a source

of trouble, due to losses - particularly the combi coil and the

regulating transductor. Later chassis are less prone to this sort of

thing, partly because of the use of later generation, higher efficiency

yokes but mainly due to more generous and better design of the wound

components. The ideal dielectric for use in the tuning capacitors is

polypropylene (either metalised or film). It's a truly won- derful

dielectric - very stable, with very small losses, and capable of

operation at high frequencies and elevated temperatures. It's also

nowadays reasonably inexpensive. Unfortunately many earlier chassis of

this type used polyester capacitors, and it's no surprise that they were

inclined to give up. When replacing the tuning capacitors in a

thyristor line output stage it's essential to use poly- propylene types

-a good range of axial components with values ranging from 0.001µF to

047µF is available from RS Components, enabling even non-standard values

to be made up from an appropriate combination. Using polypropylene

capacitors in place of polyester ones will not only ensure capacitor

reliability but will

Component Problems: The only problem with this type of circuit is the large amount of energy that shuttles back and forth at line frequency.

This places a heavy stress on certain components. Circuit losses

produce quite high temperatures, which are concentrated at certain

points, in particular the combi coil. This leads to deterioration of the

soldered joints around the coil, a common cause of failure. This can

have a cumulative effect, a high -resistance joint increasing the local

heating until the joint becomes well and truly dry -a classic symptom

with some Grundig sets. The wound components themselves can be a source

of trouble, due to losses - particularly the combi coil and the

regulating transductor. Later chassis are less prone to this sort of

thing, partly because of the use of later generation, higher efficiency

yokes but mainly due to more generous and better design of the wound

components. The ideal dielectric for use in the tuning capacitors is

polypropylene (either metalised or film). It's a truly won- derful

dielectric - very stable, with very small losses, and capable of

operation at high frequencies and elevated temperatures. It's also

nowadays reasonably inexpensive. Unfortunately many earlier chassis of

this type used polyester capacitors, and it's no surprise that they were

inclined to give up. When replacing the tuning capacitors in a

thyristor line output stage it's essential to use poly- propylene types

-a good range of axial components with values ranging from 0.001µF to

047µF is available from RS Components, enabling even non-standard values

to be made up from an appropriate combination. Using polypropylene

capacitors in place of polyester ones will not only ensure capacitor

reliability but will  also

lower the stress on other components by reducing the circuit losses

(and hence power consumption). The thyristors are also liable to fail,

as are their parallel diodes. Earlier devices were less reliable than

their successors. Since all thyristor line output stages operate in the

same way and under similar conditions, the use of later types of

thyristors and diodes in earlier circuits is a matter of mechanical

rather than electrical con- siderations. One important point should be

noted: the scan thyristor is a faster device and often has a higher

voltage rating than the flyback thyristor. The simplest course is to

keep in stock some of the later scan thyristors that incorporate an

efficiency diode - suitable types are the RCA S3900SF and the Telefunken

TD3-800H. The Telefunken device is in a TO66 package (and can be

obtained quite cheaply) while the RCA type is in a TO220 package. Either

type can be used in the scan or flyback positions and can also be used

as a replacement for the regulating thyristor used in later designs

instead of a transductor. Whenever replacing a thyristor in the line

output stage it's good practice to replace the parallel diode at the

same time. Using one of the above recom- mended devices will do this

automatically, since the thyristor and its parallel diode share the same

encapsulation - always remember to remove the old diode when this is a

separate device however, as some can exhibit high -voltage

leakage/breakdown which is not evident from a quite check with the Avo.

Apart from the wound components (including the line output transformer),

the thyristors and their parallel diodes and the tuning capacitors

several other com- ponents are prone to failure. These include the

tripler, scan/flyback rectifier diodes used to provide various supply

lines, surge limiting resistors, the scan coil coup- ling/scan

correction capacitor (replace with a metalised polypropylene type) and

regulator components such as the thyristor in later types and the

transductor driver transistor in earlier circuits.

also

lower the stress on other components by reducing the circuit losses

(and hence power consumption). The thyristors are also liable to fail,

as are their parallel diodes. Earlier devices were less reliable than

their successors. Since all thyristor line output stages operate in the

same way and under similar conditions, the use of later types of

thyristors and diodes in earlier circuits is a matter of mechanical

rather than electrical con- siderations. One important point should be

noted: the scan thyristor is a faster device and often has a higher

voltage rating than the flyback thyristor. The simplest course is to

keep in stock some of the later scan thyristors that incorporate an

efficiency diode - suitable types are the RCA S3900SF and the Telefunken

TD3-800H. The Telefunken device is in a TO66 package (and can be

obtained quite cheaply) while the RCA type is in a TO220 package. Either

type can be used in the scan or flyback positions and can also be used

as a replacement for the regulating thyristor used in later designs

instead of a transductor. Whenever replacing a thyristor in the line

output stage it's good practice to replace the parallel diode at the

same time. Using one of the above recom- mended devices will do this

automatically, since the thyristor and its parallel diode share the same

encapsulation - always remember to remove the old diode when this is a

separate device however, as some can exhibit high -voltage

leakage/breakdown which is not evident from a quite check with the Avo.

Apart from the wound components (including the line output transformer),

the thyristors and their parallel diodes and the tuning capacitors

several other com- ponents are prone to failure. These include the

tripler, scan/flyback rectifier diodes used to provide various supply

lines, surge limiting resistors, the scan coil coup- ling/scan

correction capacitor (replace with a metalised polypropylene type) and

regulator components such as the thyristor in later types and the

transductor driver transistor in earlier circuits.  There

are two basic fault conditions: when the excess current trip is

activated and the set goes dead, or no e.h.t. with the trip not

activated. The first condition is usually due to a line timebase fault,

the most common being a short-circuit flyback thyristor or its parallel

diode. A straightforward resistance check will sort this out. If this is

not the case, short-circuit the scan thyristor by soldering a wire link

between its anode and cathode. This will prevent any drive to the scan

coils and the line output transformer. If the tripping stops, the fault

could be due to the tripler, the line output transformer, a rectifier

diode fed from a winding on the latter or a short in a circuit supplied

by a scan rectifier diode. If the trip continues to operate and the

flyback thyristor/diode is not the culprit, the most likely causes are

incorrect drive to this thyristor - if possible check with a scope

against the waveform given in the manual - or a rectifier diode fed from

the combi coil. As an example of the latter, Fig. 3 shows the

arrangement used in the Finlux Peacock: the electronic trip will operate

if either D503 or D504 goes short-circuit, a fairly common fault on

these sets. The diodes can also go open-circuit/high resistance to give

the no sound with field collapse symp- tom, but that's another story (

referring to the diodes as D603/4 ). When the set is dead, h.t. is

present and the trip is not activated, suspect the following: the scan

thyristor, the efficiency diode, the line output transformer, the scan -

correction capacitor, or lack of drive to the scan thyristor. Dry

-joints can be the cause of any of these basic fault conditions,

depending on the actual circuit and where the dry -joint has occurred.

There

are two basic fault conditions: when the excess current trip is

activated and the set goes dead, or no e.h.t. with the trip not

activated. The first condition is usually due to a line timebase fault,

the most common being a short-circuit flyback thyristor or its parallel

diode. A straightforward resistance check will sort this out. If this is

not the case, short-circuit the scan thyristor by soldering a wire link

between its anode and cathode. This will prevent any drive to the scan

coils and the line output transformer. If the tripping stops, the fault

could be due to the tripler, the line output transformer, a rectifier

diode fed from a winding on the latter or a short in a circuit supplied

by a scan rectifier diode. If the trip continues to operate and the

flyback thyristor/diode is not the culprit, the most likely causes are

incorrect drive to this thyristor - if possible check with a scope

against the waveform given in the manual - or a rectifier diode fed from

the combi coil. As an example of the latter, Fig. 3 shows the

arrangement used in the Finlux Peacock: the electronic trip will operate

if either D503 or D504 goes short-circuit, a fairly common fault on

these sets. The diodes can also go open-circuit/high resistance to give

the no sound with field collapse symp- tom, but that's another story (

referring to the diodes as D603/4 ). When the set is dead, h.t. is

present and the trip is not activated, suspect the following: the scan

thyristor, the efficiency diode, the line output transformer, the scan -

correction capacitor, or lack of drive to the scan thyristor. Dry

-joints can be the cause of any of these basic fault conditions,

depending on the actual circuit and where the dry -joint has occurred.  The usual symptom is fuzzy verticals and a sawtooth effect on

diagonals. The trip may operate, possibly after period of operation.

These components set up the transductor's operating bias. Linearity

problems are usually caused by the regulator circuit, which can also be

responsible for line "hunting". In the event of lack of width in the

earlier type of circuit, check for dry -joints in the regulator circuit

and suspect the control transistor. Foldover on the left-hand side of

the screen can be caused by an open -circuit flyback diode. Foldover at

the centre of the screen with greatly reduced width is the symptom when

the efficiency diode goes open -circuit - the trip may or may not

operate. Unusual interference patterns on the screen, best viewed with

the contrast control turned to minimum and the brightness control

advanced until a distinctly visible but not over bright white raster is

obtained, can be due to the tripler if there's curved patterning on the

extreme left- hand side of the screen, the regulator clamp diode (Di505

in Fig. 2) if there's curved interference just to the left of centre, or

the flyback thyristor drive circuit if there's a single vertical line

of patterning about four fifths of the way to the right of the screen.

The usual symptom is fuzzy verticals and a sawtooth effect on

diagonals. The trip may operate, possibly after period of operation.

These components set up the transductor's operating bias. Linearity

problems are usually caused by the regulator circuit, which can also be

responsible for line "hunting". In the event of lack of width in the

earlier type of circuit, check for dry -joints in the regulator circuit

and suspect the control transistor. Foldover on the left-hand side of

the screen can be caused by an open -circuit flyback diode. Foldover at

the centre of the screen with greatly reduced width is the symptom when

the efficiency diode goes open -circuit - the trip may or may not

operate. Unusual interference patterns on the screen, best viewed with

the contrast control turned to minimum and the brightness control

advanced until a distinctly visible but not over bright white raster is

obtained, can be due to the tripler if there's curved patterning on the

extreme left- hand side of the screen, the regulator clamp diode (Di505

in Fig. 2) if there's curved interference just to the left of centre, or

the flyback thyristor drive circuit if there's a single vertical line

of patterning about four fifths of the way to the right of the screen.The aim of this article has been to provide a general guide to servicing rather than to list faults common to particular models. Much useful information on individual

chassis with thyristor line output stages has appeared in previous issues of Obsolete Technology Tellye !- refer to the following as required: Search with the tag Thyristors at the bottom of the post to select all posts with this argument on various fabricants.

Isolated mains chassis thyristor technology:

A supply circuit for television receivers in which power source isolation is effected via a backward transformer. For the sake of achieving an insusceptibility to interferences, the operating frequency is equal to the line frequency. According to the invention, the supplied energy is controlled by varying the switch-on time during one period of the line frequency, in that the disconnecting time position is changed with the aid of a thyristor switching stage.

A supply circuit for television receivers in which power source isolation is effected via a backward transformer. For the sake of achieving an insusceptibility to interferences, the operating frequency is equal to the line frequency. According to the invention, the supplied energy is controlled by varying the switch-on time during one period of the line frequency, in that the disconnecting time position is changed with the aid of a thyristor switching stage.1. A su

an input transformer having a secondary winding connected to the horizontal output stage for providing the energy required thereby and a primary winding adapted for connection to the power source and being electrically isolated from the secondary winding and the horizontal output stage;

electronic switch means connected in series with the primary winding of the transformer;

first switching control means for switching on the electronic switch means as a function of line frequency; and

second switching control means for switching off the electronic switch means as a function of the energy required by the horizontal output stage, whereby the supply circuit provides the horizontal output stage with the required energy from the power source while also electrically isolating the horizontal output stage from the power source.

2. A supply circuit as described in claim 1, wherein the electronic switch means comprises a thyristor stage.

3. A supply circuit as described in claim 1, wherein the thyristor stage comprises a thyristor and a diode connected in inverse parallel manner, the gate electrode of the thyristor being connected to the first switching control means for turning on the thyristor.

4. A supply circuit as described in claim 3, wherein the first switching control means includes a horizontal deflection oscillator.

5. A supply circuit as described in claim 4, additionally comprising an isolation transformer connected between the thyristor gate and the horizontal deflection oscillator.

6. A supply circuit as described in claim 2, wherein the second switching control means comprises a series resonant circuit having an adjustable resonant frequency, said circuit being connected in parallel with the thyristor stage for causing commutation of the current in the thyristor stage.

7. A supply circuit as described in claim 6, wherein the series resonant circuit includes a transductor having a control winding, and the second switching control means additionally comprises a control circuit adapted to receive a signal from a high voltage transformer of the horizontal output stage and to provide in response thereto an output signal to the control winding of the transductor, said output signal varying in accordance with the signal from the high voltage transformer for varying the inductance of the transductor.

Owing to the various attachments which are capable of being operated in connection with a television receiver, it has increasingly become necessary, for safety reasons, to provide for isolation of the power source the television receiver.

In conventional types of circuits employing backward transformers for effecting the source isolation, it is customary to control the energy supply by way of inserting a transistorized control stage.

The use of transistors in such a circuit part, however, has proved to be problematic owing to the fact that the transistors are sensitive to any case of exceeding the prescribed operational values.

From the German technical journal "Funkschau" 1975, No. 5, page 40 there has already become known a

In order to eliminate as far as possible the danger of noise influences as linked thereto, the actually advantageous thyristor switching stage involves a rather considerable investment.,

It is the object of the invention, therefore, with respect to a circuit of the type mentioned hereinbefore, to avoid the described disadvantages of the conventional arrangments, and to safeguard an operationally reliable control of the supplied energy.

This object is achieved in that the energy as supplied to the horizontal (line) output stage is capable of being controlled by means of a thyristor switching stage arranged in series with the primary winding of the input transformer, with first switching means, in dependence upon the line frequency, switching the thyristor switching stage to the conducting state, and with further switching means serving to block the thyristor switching stage in dependence upon the required energy.

Further details and advantages of the invention may be taken from the patent claims as well as from the following description of the accompanying drawing.

FIG. 1 shows one example of embodiment of the invention.

The horizontal output (final) stage 20 is connected via the input transformer 10 including the primary winding 11 and the secondary winding 12, to the source of supply current B.

The horizontal output (final) stage 20 is connected via the input transformer 10 including the primary winding 11 and the secondary winding 12, to the source of supply current B. As an example relating to the horizontal output (final) stage there is shown in FIG. 1 a thyristor circuit as described in the company publication "Deflection, Power Supply and Correction Circuits for 110° Color Picture Tube A67 - 150x with Toroidal Yoke", No. 59-72-E of Standard Elektrik Lorenz AG, dated Apr. 20, 1972.

By the input transformer 10, the horizontal output stage 20 is galvanically separated from the source of supply current B, i.e. also from the power source. The most important function units of the horizontal output stage will now be mentioned briefly hereinafter.

The reference numeral 21 indicates the schematically shown combined inductive component consisting of deflecting coils and EHT transformer.

The switching stage 22 consisting of a thyristor and of an anti-parallel connected diode, represents the stage controlling the line sweep while the similarly designed switching stage 23 is the so-called commutating switch.

Between these two switching stages there is connected the commutating inductive component 25 and the commutating capacitor consisting of a capacitor combination 26.

The primary circuit of the inductive component 10 designed as an input transformer, is connected to the supply source B, at the "plus" and "minus" terminals of which the rectified power source voltage is available. The input transformer 10 comprises the primary winding 11 and the secondary winding 12. In series with the primary winding 11 there is arranged a thyristor switching stage consisting of a thyristor 13 and of a diode 14, with both the thyristor and the diode being connected antiparallel.

The thyristor 13 is controlled in this case by inserting an isolating transformer 19, by the horizontal oscillator 18, which means to imply that the operating frequency of the supply circuit including the input transformer 10 is identical to that of the horizontal final stage 20.

The switch-on time position, i.e. the one at which the thyristor 13 is switched to the conducting state, is determined by the control pulse from the horizontal oscillator 18.

Th

e aforementioned variation of the resonant frequency of the series-resonant circuit, may be carried out, on principle, by a capacitance variation of the capacitor 16, as well as by changing the inductance 15, or else by both.

e aforementioned variation of the resonant frequency of the series-resonant circuit, may be carried out, on principle, by a capacitance variation of the capacitor 16, as well as by changing the inductance 15, or else by both. In the shown example of embodiment there has been chosen a variation of the inductance, in which case, as an inductive component, a transductor is inserted in such a way that its operating winding is in series with the capacitor 16. Transductor 15 provides an inductance that varies in accordance with a DC signal applied thereto. If now, in accordance with stipulations, the energy supply is to be controlled in dependence upon the energy requirement, a corresponding control circuit will have to be provided for.

The energy consumed in the horizontal final stage can be measured by the value of the voltage of the kick-back pulse at the EHT transformer. In order to obtain this value, a tap 211 is schematically shown at the inductive component 21 of the horizontal final stage 20. This tap is connected to a control circuit 17.

As already mentioned, a transductor 15 is used as the adjustable inductive component of the series resonant circuit, whose inductance is capable of being varied by varying the current or voltage as applied to the control winding. At the same time, the transductor effects a galvanic separation. The control circuit 17 into the output circuit of which, according to FIG. 1, there is connected the control winding of the transductor 15, thus serves to convert the value of the voltage of the kickback pulse available as the input or control quantity, into a corresponding value for adjusting the inductive component 15.

It should still be mentioned that the input transformer 10 is operated as a backward transformer comprising a correspondingly polarized diode 24 in the secondary circuit, which is of advantage for reasons of dimensioning the input transformer 10.

LOEWE CT5067U CHASSIS C5000 20AX INTEGRAL THYRISTOR-RECTIFIER DEVICEA semiconductor switching device comprising a silicon controlled rectifier (SCR) and a diode rectifier integrally connected in parallel with the SCR in a single semiconductor body. The device is of the NPNP or PNPN type, having gate, cathode, and anode electrodes. A portion of each intermediate N and P region makes ohmic contact to the respective anode or cathode electrode of the SCR. In addition, each intermediate region includes a highly conductive edge portion. These portions are spaced from the adjacent external regions by relatively low conductive portions, and limit the conduction of the diode rectifier to the periphery of the device. A profile of gold recombination centers further electrically isolates the central SCR portion from the peripheral diode portion.

That class of thyristors known as controlled rectifiers are semiconductor switches having four semiconducting regions of alternate conductivity and which employ anode, cathode, and gate electrodes. These devices are usually fabricated from silicon. In its normal state, the silicon controlled rectifier (SCR) is non-conductive until an appropriate voltage or current pulse is applied to the gate electrode, at which point current flows from the anode to the cathode and delivers power to a load circuit. If the SCR is reverse biased, it is non-conductive, and cannot be turned on by a gating signal. Once conduction starts, the gate loses control and current flows from the anode to the cathode until it drops below a certain value (called the holding current), at which point the SCR turns off and the gate electrode regains control. The SCR is thus a solid state device capable of performing the circuit function of a thyratron tube in many electronic applications. In some of these applications, such as in automobile ignition systems and horizontal deflection circuits in television receivers, it is necessary to connect a separate rectifier diode in parallel with the SCR. See, for example, W. Dietz, U. S. Pat. Nos. 3,452,244 and 3,449,623. In these applications, the anode of the rectifier diode is connected to the cathode of the SCR, and the cathode of the rectifier is connected to the SCR anode. Thus, the rectifier diode will be forward biased and current will flow through it when the SCR is reverse biased; i.e., when the SCR cathode is positive with respect to its anode. For reasons of economy and ease of handling, it would be preferable if the circuit function of the SCR and the associated diode rectifier could be combined in a single device, so that instead of requiring two devices and five electrical connections, one device and three electrical connections are all that would be necessary. In fact, because of the semiconductor profile employed, many SCR's of the shorted emitter variety inherently function as a diode rectifier when reverse biased. However, the diode rectifier function of such devices is not isolated from the controlled rectifier portion, thus preventing a rapid transition from one function to the other. Therefore, it would be desirable to physically and electrically isolate the diode rectifier portion from that portion of the device which functions as an SCR.

LOEWE CT5067U CHASSIS C5000 20AX LINE DEFLECTION WITH THYRISTOR SWITCH TECHNOLOGY OVERVIEW.

(Thyristor Horizontalsteuerung UND ABLENKUNG)

Description:

1. A horizontal deflection circuit for generating the deflection current in the deflection coil of a television picture tube wher

German Aus

The first controlled switch also forms part of a second branch circuit where it is connected in series with a second current source and a reactance capable of oscillating. When the first switch is closed, the reactance, consisting essentially of a coil and a capacitor, receives energy from the second current source during a fixed time interval. This energy which is taken from the second current source corresponds to the circuit losses caused during the previous deflection cycle.

As can be seen, such a circuit needs two different, separate inductive elements, it being known that inductive elements are expensive to manufacture and always have a certain volume determined by the electrical properties required.

The object of the invention is to reduce the amount of inductive elements required.

The invention is characterized in that the input inductor and the commutating inductor are combined in a unit designed as a transformer which is proportioned so that the open-circuit inductance of the transformer is essentially equal to the value of the input inductor, while the short-circuit inductance of the transformer is essentially equal to the value of the commutating inductor, and that the second switch is connected in series with the dc voltage source and a first winding of the transformer.

This solution has an added advantage in that, in mass production, both the open-circuit and the short-circuit inductance are reproducible with reliability.

According to another feature of the invention, the electrical isolation between the windings of the transformer is such that the transformer operates as an isolation transformer between the supply and the subcircuits connected to a second winding or to additional windings of the transformer. In this manner, the transformer additionally provides reliable mains isolation.

According to a further feature of the invention, the second switch is connected between ground and that terminal of the first winding of the transformer not connected to the supply potential. This simplifies the control of the switch.

According to a further feature of the invention, to regulate the energy supply, the second winding of the transf

The advantage gained by this measure lies in the fact that the control takes place on the side separated from the mains, so no separate isolation device is required for the gating of the third switch. Further details and advantages will be apparent from the following description of the accompanying drawings and from the claims. In the drawings,

FIG. 1 is a basic circuit diagram of the arrangement disclosed in German Auslegeschrift (DT-AS) No. 1,537,308;

FIG. 2 shows a first embodiment of the horizontal deflection circuit according to the invention, and

FIG. 3 shows a development of the horizontal deflection circuit according to the invention.

FIG. 1 shows the essential circuit elements of the horizontal deflection circuit known from the German Auslegeschrift (DT-AS) No. 1,537,308 referred to by way of introduction.

Connected in series with a dc voltage source UB is an input inductor Le and a bipolar, controlled switch S2. In the following, this switch will be referred to as the "second switch"; it is usually called the "commutating switch" to indicate its function.

In known circuits, the second switch S2 consists of a controlled rectifier and a diode connected in inverse parallel.

The second switch S

2 also forms part of a second circuit which contains, in addition, a commutating inductor Lk, a commutating capacitor Ck, and a first switch S1. The first switch S1, controlling the horizontal sweep, is constructed in the same manner as the above-described second switch S2, consisting of a controlled rectifier and a diode in inverse parallel. Connected in parallel with this first switch is a deflection-coil arrangement AS with a capacitor CA as well as a high voltage generating arrangement (not shown). In FIGS. 1, 2, and 3, this arrangement is only indicated by an arrow and by the reference characters Hsp. The operation of this known horizontal deflection circuit need not be explained here in detail since it is described not only in the German Auslegeschrift referred to by way of introduction, but also in many other publications.

FIGS. 2 and 3 show the horizontal deflection circuit modified in accordance with the present invention. Like circuit elements are designated by the same reference characters as in FIG. 1.

FIG. 2 shows the basic principle of the invention. The two inductors Le and Lk of FIG. 1 have been replaced by a transformer U. To be able to serve as a substitute for the two inductors Le and Lk, the transformer must be proportioned in a special manner. Regardless of the turns ratio, the open-circuit inductance of the transformer is chosen to be essentially equal to the value of the input inductor Le, and the short-circuit inductance of the transformer is essentially equal to the value of the commutating inductor Lk.

To permit the second switch S2 to be utilized for the connection of the dc voltage source UB, it is included in the circuit of that winding U1 of the transformer connected to the dc voltage UB.

In principle, it is of no consequence for the operation of the switch S2 whether it is inserted on

In compliance with pertinent safety regulations, the transformer U may be designed as an isolation transformer and can thus provide mains separation, which is necessary for various reasons. It is known from German Offenlegungschrift (DT-OS) No. 2,233,249 to provide dc isolation by designing the commutating inductor as a transformer, but this measure is not suited to attaining the object of the present invention.

If the energy to be taken from the dc voltage source is to be controlled as a function of the energy needed in the horizontal deflection circuit and in following subcircuits, the embodiment of the horizontal deflection circuit of FIG. 3 may be used.

The circuit including the winding U2 of the transformer U contains a third controlled switch S3, which, too, is inserted on the grounded side of the winding U2 for the reasons mentioned above. This third switch S3, just as the second switch S2, is operated at the frequency of a horizontal oscillator HO, but a control circuit RS whose input l is fed with a controlled variable is inserted between the oscillator and the switch S3. Depending on this controlled variable, the controlled rectifier of the third switch S3 can be caused to turn on earlier. A suitable controlled variable containing information on the energy consumption is, for example, the flyback pulse capable of being taken from the high voltage generating circuit (not shown). Details of the operation of this kind of energy control are described in applicant's German Offenlegungsschrift (DT-OS) No. b 2,253,386 and do not form part of the present invention.

With mains isolation, the additional, third switch S3 shown here has the advantage of being on the side isolated from the mains and eliminates the need for an isolation device in the control lead of the controlled rectifier.

As an isolation transformer, the transformer U may also carry additional windings U3 and U4 if power is to be supplied to the audio output stage, for example; in addition, the first switch S1 may be gated via such an additional winding.

The points marked at the windings U1 and U2 indicate the phase relationship between the respective voltages. Connected in parallel with the winding U1 and the second switch S2 is a capacitor CE which completes the circuit for the horizontal-frequency alternating current; this serves in particular to bypass the dc voltage source or the electrolytic capacitors contained therein.

LOEWE CT5067U CHASSIS C5000 20AX Electron beam deflection circuit including thyristors Further Discussion and deepening of knowledge, Thyristor horizontal output circuits:

2. A deflection circuit as claimed in claim 1, wherein said amount of additional current is greater than or equal to 5 per cent of the peak-to-peak value of the current flowing through the deflection winding.

3. A deflection circuit as claimed in claim 1, wherein said means for drawing a substantial amount of additional current through said first switching means comprises a resistor connected in parallel to said first capacitor.

4. A deflection circuit as claimed in claim 1, wherein said means for drawing an additional current is formed by connecting said first and second energy sources in series so that the current charging said reactive circuit means forms the said additional current.

5. A deflection circuit as claimed in claim 1, further including a series combination of an autotransformer winding and a second high-value capacitor, said combination being connected in parallel to said first switching means, wherein said autotransformer comprises an intermediate tap located between its terminals respectively connected to said first switching means and to said second capacitor, said tap delivering, during said trace portion, a suitable DC supply voltage lower than the voltage across said second capacitor; and wherein said means for drawing a substantial amount of additional current comprises a load to be fed by said supply voltage and having one terminal connected to ground; and further controllable switching means controlled to conduct during at least part of said trace portion and to remain cut off during said retrace portion, said further switching means being connected between said tap and the other terminal of said load.

The present invention relates to electron beam deflection circuits including thyristors, such as silicon controlled rectifiers and relates, in particular, to horizontal deflection circuits for television receivers.

The present invention relates to electron beam deflection circuits including thyristors, such as silicon controlled rectifiers and relates, in particular, to horizontal deflection circuits for television receivers. The present invention constitutes an improvement in the circuit described in U.S. Pat. No. 3,449,623 filed on Sept. 6, 1966, this circuit being described in greater detail below with reference to FIGS. 1 and 2 of the accompanying drawings. A deflection circuit of this type comprises a first thyristor switch which allows the conenction of the horizontal deflection winding to a constant voltage source during the time interval used for the transmisstion of the picture signal and for applying this signal to the grid of the cathode ray tube (this interval will be termed the "trace portion" of the scan), and a second thyristor switch which provides the forced commutation of the first one by applying to it a reverse current of equal amplitude to that which passes through it from the said voltage source and thus to initiate the retrace during the horizontal blanking interval.

The present invention constitutes an improvement in the circuit described in U.S. Pat. No. 3,449,623 filed on Sept. 6, 1966, this circuit being described in greater detail below with reference to FIGS. 1 and 2 of the accompanying drawings. A deflection circuit of this type comprises a first thyristor switch which allows the conenction of the horizontal deflection winding to a constant voltage source during the time interval used for the transmisstion of the picture signal and for applying this signal to the grid of the cathode ray tube (this interval will be termed the "trace portion" of the scan), and a second thyristor switch which provides the forced commutation of the first one by applying to it a reverse current of equal amplitude to that which passes through it from the said voltage source and thus to initiate the retrace during the horizontal blanking interval.A undirectional reverse blocking triode type thyristor or silicon controlled rectifier (SCR), such as that used in the aformentioned circuit, requires a certain turn-off time between the instant at which the anode current ceases and the instant at which a positive bias may be applied to it without turning it on, due to the fact that there is still a high concentration of free carriers in the vicinity of the middle junction, this concentration being reduced by a process of recombination independently from the reverse polarity applied to the thyristor. This turn-off time of the thyristor is a function of a number of parameters such as the junction temperature, the DC current level, the decay time of the direct current, the peak level of the reverse current applied, the amplitude of the reverse anode to cathode voltage, the external impedance of the gate electrode, and so on, certain of these varying considerably from one thyristor to another.

In horizontal deflection circuits for television receivers, the flyback or retrace time is limited to approximately 20 percent of the horizontal scan period, the retrace time being in the case of the CCIR standard of 625 lines, approximately 12 microseconds and, in the case of the French standard of 819 lines, approximately 9 microseconds. During this relatively short interval, the thyristor has to be rendered non-conducting and the electron beam has to be returned to the origin of the scan. The first thyristor is blocked by means of a series resonant LC circuit which is subject to a certain number of restrictions (limitations as to the component values employed) due to the fact that, inter alia, it simultaneously determines the turn-off time of the circuit which blocks the thyristor and it forms part of the series resonant circuit which is to carry out the retrace. To obtain proper operation of the deflection circuit of the aforementioned Patent, especially when used for the French standard of 819 lines per image, the values of the components used have to subject to very close tolerances (approximately 2%), which results in high costs.

The improved deflection circuit, object o

f the present invention, allows the lengthening of the turn-off time of the circuit for turning the scan thyristor off, without altering the values of the LC circuit, which are determined by other criteria, and without impairing the operation of the circuit.

According to the invention, there is provided an electron beam deflection circuit for a cathode ray tube with electromagentic deflection by means of a sawtooth current waveform having a trace portion and a retrace portion, said circuit comprising: a deflection winding; a first source of electrical energy formed by a first capacitor; first controllable switching means comprising a parallel combination of a first thyristor and a first diode, connected together to conduct in opposite directions, for connecting said winding to said first source during said trace portion when said first switching means is turned on; a second source of electrical energy including a first inductive energy storage means coupled to a voltage supply; reactive circuit means including a combination of inductive and capacitive reactances for storing the energy supplied by the said second source; a second controllable switching means, substantially identical with the first one, for completing a circuit including said reactive circuit means and said first switching means, when turned on, so as to pass through said first thyristor an oscillatory current in the opposite direction to that which passes through it from said first source and to turn it off after these two currents cancel out, the oscillatory current then flowing through said first diode for an interval termed the circuit turn-off time which has to be greater than the turn-off time of said first thyristor; and means for drawing duing at least a part of said trace portion a substantial amount of additional current from said first switching means in the direction of conduction of said first diode, whereby said circuit turn-off time is lengthened in proportion to the amount of said additional current, without altering the values of the reactances in the reactive circuit by shifting the waveform of the current flowing through said first switching means towards the negative by an amount equal to that of said additional current.

A further object of the invention consists in using the supplementary current in the recovery diode of the first switching means to produce a DC voltage which may be used as a power supply for the vertical deflection circuit of the television receiver, for example.

The invention will be better understood and other features and advantages thereof will become apparent from the following description and the accompanying drawings, given by way of example, and in which:

FIG. 1 is a schematic circuit diagram partially in bloc diagram form of a prior art deflection circuit according to the aforementioned Patent;

FIG. 2 shows waveforms of currents and voltages generated at various points in the circuit of FIG. 1;

FIG. 2 shows waveforms of currents and voltages generated at various points in the circuit of FIG. 1;FIG. 3 is a schematic diagram of a deflection circuit according to the invention which allows the principle of the improvement to be explained;

FIG. 4 is a diagram of the waveforms of the current through the first switching means 4, 5 of the circuit of FIG. 3;

FIG. 5 is a circuit diagram of another embodiment of the circuit according to the invention;

FIG. 6 is a schematic representation of the preferred embodiment of the circuit according to the invention; and

FIG. 7 shows voltage waveforms at various points of the high voltage autotransformer 21 of FIG. 6.

In all these Figures the same reference numerals refer to the same components.

FIG. 1 shows the horizontal deflection circuit described and claimed in the U.S. Pat. No. 3,449,623 mentioned above, which comprises a first source of electrical energy in the shape of a first capacitor 2 having a high capacitance C 2 for supplying a substantially constant voltage Uc 2 across its terminals. A first terminal of the first capacitor 2 is connected to ground, whilst its second terminal which supplies a positive voltage is connected to one of the terminals of a horizontal deflection winding shown as a first inductance 1. A first switching means 3, consisting of a first reverse blocking triode thyristor 4 (SCR) and a first recovery diode 5 in parallel, the two being interconnected to conduct current in opposite directions, is connected in parallel with the series combination formed by the deflection winding 1 and the first capacitor 2. The assembly of components 1, 2, 4 and 5 forms the final stage of the horizontal deflection circuit in a television receiver using electromagnetic delfection.

FIG. 1 shows the horizontal deflection circuit described and claimed in the U.S. Pat. No. 3,449,623 mentioned above, which comprises a first source of electrical energy in the shape of a first capacitor 2 having a high capacitance C 2 for supplying a substantially constant voltage Uc 2 across its terminals. A first terminal of the first capacitor 2 is connected to ground, whilst its second terminal which supplies a positive voltage is connected to one of the terminals of a horizontal deflection winding shown as a first inductance 1. A first switching means 3, consisting of a first reverse blocking triode thyristor 4 (SCR) and a first recovery diode 5 in parallel, the two being interconnected to conduct current in opposite directions, is connected in parallel with the series combination formed by the deflection winding 1 and the first capacitor 2. The assembly of components 1, 2, 4 and 5 forms the final stage of the horizontal deflection circuit in a television receiver using electromagnetic delfection.The deflection circuit also includes a drive stage for this final stage which here controls the turning off of the first thyristor 4 to produce the retrace or fly-back portion of the scan during the line-blanking intervals i.e. while the picture signal is not transmitted. This driver stage comprises a second voltage source in the shape of a DC power supply 6 which delivers a constant high voltage E. The negative terminal of the power supply 6 is connected to ground and its positive terminal to one of the terminals of a second inductance 7 of relatively high value, which draws a substantially lineraly varying current from the power supply 6 to avoid its overloading. The other terminal of th

The respective values of the third inductance 8 (L 8 ) and of the second capacitor 9 (C 9 ) are principally selected so that, on the one hand, one half-cycle of oscillation of the first series resonant circuit L 8 - C 9 , (i.e. π √ L 8 . C 9 ) is longer than the turn-off time of the first thyristor 4, but still is as short as possible since this time interval determines the speed of the commutation of the thyristor 4, and, on the other hand, one half-cycle of oscillation of another series resonant circuit formed by L 1 , L 8 and C 9 , i.e. π √ (L 1 + L 8 ) . C 9 , is substantially equal to the required retrace time interval (i.e. shorter than the horizontal blanking interval).

The gate (control electrode) of the second thyristor 11 is coupled to the output of the horizontal oscillator 13 of the television receiver by means of a first pulse transformer 14 and a first pulse shaping circuit 15 so that it is fed short triggering pulses which are to turn it on.

The gate of the first thyristor 4 fed with signals of a substantially rectangular waveform which are negative during the horizontal blanking intervals, is coupled to a winding 16 by means of a second pulse shaping circuit 17, the winding 16 being magnetically coupled to the second inductance 7 to make up the secondary winding of a transformer of which the inductance 7 forms the primary winding. It will be noted here that it is also possible to couple the secondary winding 16 magnetically to a primary winding connected to a suitable output (not shown) of the horizontal oscillator 13.

The operation of a circuit of this type will be explained below with reference to FIG. 2 which shows the waveforms at various points in the circuit of FIG. 1 during approximately one line period.

FIG. 2 is not to scale since one line period (t 7 - t 0 ) is equal to 64 microseconds in the case of 625 lines and 49 microseconds in the case of 819 lines, while the durations of the respective horizontal blanking intervals are approximately 12 and 9.5 microseconds.

FIG. 2 is not to scale since one line period (t 7 - t 0 ) is equal to 64 microseconds in the case of 625 lines and 49 microseconds in the case of 819 lines, while the durations of the respective horizontal blanking intervals are approximately 12 and 9.5 microseconds.Waveform A shows the form of the current i L1 passing through deflection winding 1, this current having a sawtooth waveform substantially linear from t 0 to t 3 and from t 5 to t 7 , and crossing zero at time instants t 0 and t 7 , and reaching values of + I 1m and - I 1m , at time instants t 3 and t 5 respectively, these being its maximum positive and negative amplitudes.

During the second half of the trace portion of the horizontal deflection cycle, that is to say from t 0 to t 3 , the thyristor 4 of the first switching means 3 is conductive and makes the high value capacitor 2 discharge through the deflector winding 1, which has a high inductance, so that current i L1 increases linearly.

A few microseconds (5 to 8 μ s) before the end of the trace portion, i.e. at time instant t 1 , the trigger of the second thyristor 11 receives a short voltage pulse V G11 which causes it to turn on as its anode is at this instant at a positive potential with respect to ground, which is due to the charging of the second capacitor 9 through inductances 7 and 8 by the voltage E from the power supply 6.

When thyristor 11 is made conductive at time t 1 , on the one hand, inductance 7 is connected between ground and the voltage source 6 and a linearly increasing current flows through it and, on the other hand, the reactive circuit 8, 9 forms a loop through the second and first switching means 10 and 3, thus forming a resonant circuit which draws an oscillatory current i 8 ,9 of frequency ##EQU1##

This oscillatory current i 8 ,9 will pass through the first switching means 3, i.e. thyristor 4 and diode 5, in the opposite direction to that of current i L1 . Since the frequency f 1 is high, current i 8 ,9 will increase more rapidly than i L1 and will reach the same level at time t 2 , that is to say i 8 ,9 (t 2 ) = -i L1 (t 2 ) and these currents will cancel out in the thyristor 4 in accordance with the well known principle of forced commutation. After time instant t 2 , current i 8 ,9 continues to increase more rapidly than i L1 , but the difference between them (i 8 ,9 - i L1 ) passes the diode 5 (see wave form B) until it becomes zero at time instant t 3 which is the turn off time instant of the first switching means 3, at which the retrace begins.

The interval between the time instant t 2 and t 3 , i.e. (t 3 -t 2 ), during which diode 5 is conductive and the thyristor is reverse biased will be termed in what follows the circuit turn-off time and it should

The retrace which stated at time t 3 takes place during one half-cycle of the resonant circuit formed by reactances L 1 , L 8 and C 9 , i.e. during the interval between t 3 and t 5 . In the middle of this interval i.e. at time instant t 4 , both i L1 (waveform A) and i 8 ,9 (waveform D) pass through zero and change their sign, whereas the voltage at the terminals of the first switching means 3 (V 3 , waveform E) passes through a maximum. Thus, from t 4 onwards, thyristor 11 will be reverse biased and diode 12 will conduct the current from the resonant circuit 1, 8 and 9 in order to turn the second thyristor 11 off.

At time instant t 5 , when current i L1 has reached - I 1m and when voltage v 3 falls to zero, diode 5 of the first switching means 3 becomes conductive and the trace portion of scan begins.

Current i 8 ,9 nevertheless continues to flow in the resonant circuit 8, 9 through diodes 5 and 12, which causes a break to appear in waveform D at t 5 , and a negative peak to appear in waveform D and a positive one in waveform B in the interval between t 5 and t 6 , these being principally due to the distributed capacities of coil 1 or to an eventual capacitor (not shown) connected in parallel to the first switching means 3.

At time instant t 6 , diode 12 of the second switching means 10 ceases to conduct after having allowed thyristor 11 time to become turned off completely.

The level of current i 8 ,9 at time instant t 5 (i.e. I c ) as well as the negative peak I D12 in i 8 ,9 and the positive peak I D5 in i 5 depend on the values of L 8 and C 9 in the same way as does the turn-off time of the circuit (t 3 - t 2 ). If, for example, L 8 and C 9 , are increased I D5 increases towards zero and this could cause diode 5 to be cut off in an undesirable fashion. I c also increases towards zero, which is liable to cause diode 12 to be blocked and thyristor 11 to trigger prematurely.

From the foregoing it can be clearly seen that the choice of values for L 8 and C 9 is subject to four limitations which prevent the values from being increased to lengthen the turn-off time of the driver circuit of first switching thyristor 4 so as to forestall its spurious triggering.

Waveform F shows the voltage v G4 obtained at the gate of thyristor 4 from the secondary winding 16 coupled to the inductor 7. This voltage is positive from t 0 to t 1 and from t 6 to t 7 and is negative between t 2 and t 6 i.e. while the second switching means 10 is conducting.

The present invention makes the lengthening of the turn-off time of thyristor 4 possible without altering the parameters of the circuit such as inductance 8 and capacitor 9.

In the circuit shown in FIG. 3, which illustrates the principle of the present invention, means are added to the circuit in FIG. 1 which enable the turn-off time to be lengthened by connecting a load to diode 5 so as to increase the current which flows through it during the time that it is conductive. These means are here formed by a resistor 18 connected in parallel with a capacitor 20 (which replaces capacitor 2) which is of a higher capacitance so that, in practice, it holds its charge during at least one half of the line period. FIG. 4, which shows the waveform of the current in the first switching means 3 for a circuit as shown in FIG. 3, makes it possible to explain how this lenthening of the turn-off time is achieved.

In the circuit shown in FIG. 3, which illustrates the principle of the present invention, means are added to the circuit in FIG. 1 which enable the turn-off time to be lengthened by connecting a load to diode 5 so as to increase the current which flows through it during the time that it is conductive. These means are here formed by a resistor 18 connected in parallel with a capacitor 20 (which replaces capacitor 2) which is of a higher capacitance so that, in practice, it holds its charge during at least one half of the line period. FIG. 4, which shows the waveform of the current in the first switching means 3 for a circuit as shown in FIG. 3, makes it possible to explain how this lenthening of the turn-off time is achieved.In FIG. 4, the broken lines show the waveform of the current in the first switch device 3 in the circuit of FIG. 1, this waveform being produced by adding waveforms B and C of FIG. 2. The current i 4 above the axis flows through thyristor 4 and current i 5 below the axis flows through diode 5. When the capacitance C 20 of the capacitor in series with the deflector coil is increased to some tens of microfarads (C 2 having been of the order of 1 μ F) and when there is connected in parallel with capacitor 20 a resistor 18 the value of which is calculated to draw a strong current I R18 from capacitor 20, that is to say a current at least equal to 0,1 I m (I m being of the order of some tens of amperes), current I R18 is added to that i 5 which flows through diode 5 without in any way altering the linearity of the trace portion nor the oscillatory commutation of thyristor 4 which is brought about by the resonant circuit L 8 , C 9 .

The fact of loading capacitor C 20 by means of a resistor 18 thus has the effect of permanently displacing the waveform of the current in the negative direction by I R18 . Thus, during the trace portion of the scan, the transfer of the current from the diode 5 to the thyristor 4 begins at time t 10 instead of t 0 , that is to say with a delay proportional to I R18 . The effect of the triggering pulse delivered by the horizontal oscillator (13 FIG. 1) to the second thyristor 11 at time instant t 1 , will be to start the commutation process of the first thyristor 4 when the current it draws is less by I R18 than that i 4 (t 1 ) which it would have been drawing had there been no resistor 18. Because of this, the turn-off time of the thyristor 4 proper, which as has been mentioned increases with the maximum current level passing throught it, is slightly reduced. Moreover, because the oscillatory current i 8 ,9 (FIG. 2) from circuit L 8 , C 9 which flows through thyristor 4 in the opposite direction is unchanged, it reaches a value equal to that of the current i L1 (FIG. 1) flowing in the coil 1 in a shorter time, that is to say at time t 12 . Diode 5 will thus take the oscillatory current i 8 ,9 (FIG. 2) over in advance with respect ro time instant t 2 and will conduct it until it reaches zero value at a time instant t 13 later than t 3 , the amounts of advance (t 2 - t 12 ) and delay (t 13 - t 3 ) being practically equal.

It can thus be seen in FIG. 4 that the circuit turn-off time T R of a circuit according to the invention and illustrated by FIG. 3 is distinctly longer than that T r of the circuit in FIG. 1. This increase in the turn-off time (T R - T r ) depends on the current I R18 and increases therewith.

It can thus be seen in FIG. 4 that the circuit turn-off time T R of a circuit according to the invention and illustrated by FIG. 3 is distinctly longer than that T r of the circuit in FIG. 1. This increase in the turn-off time (T R - T r ) depends on the current I R18 and increases therewith.It should be noted at this point that the current I R18 produces a voltage drop at the terminals of the resistor the only effect of which is to heat up the resistor since the level of this voltage (40 to 60 volts) does not necessarily have a suitable value to be used as a voltage supply for other circuits in an existing transistorised television receiver.